PCX Magnet Upgrade

Complete upgrade to the magnetic confinement system for the Plasma Couette Experiment.

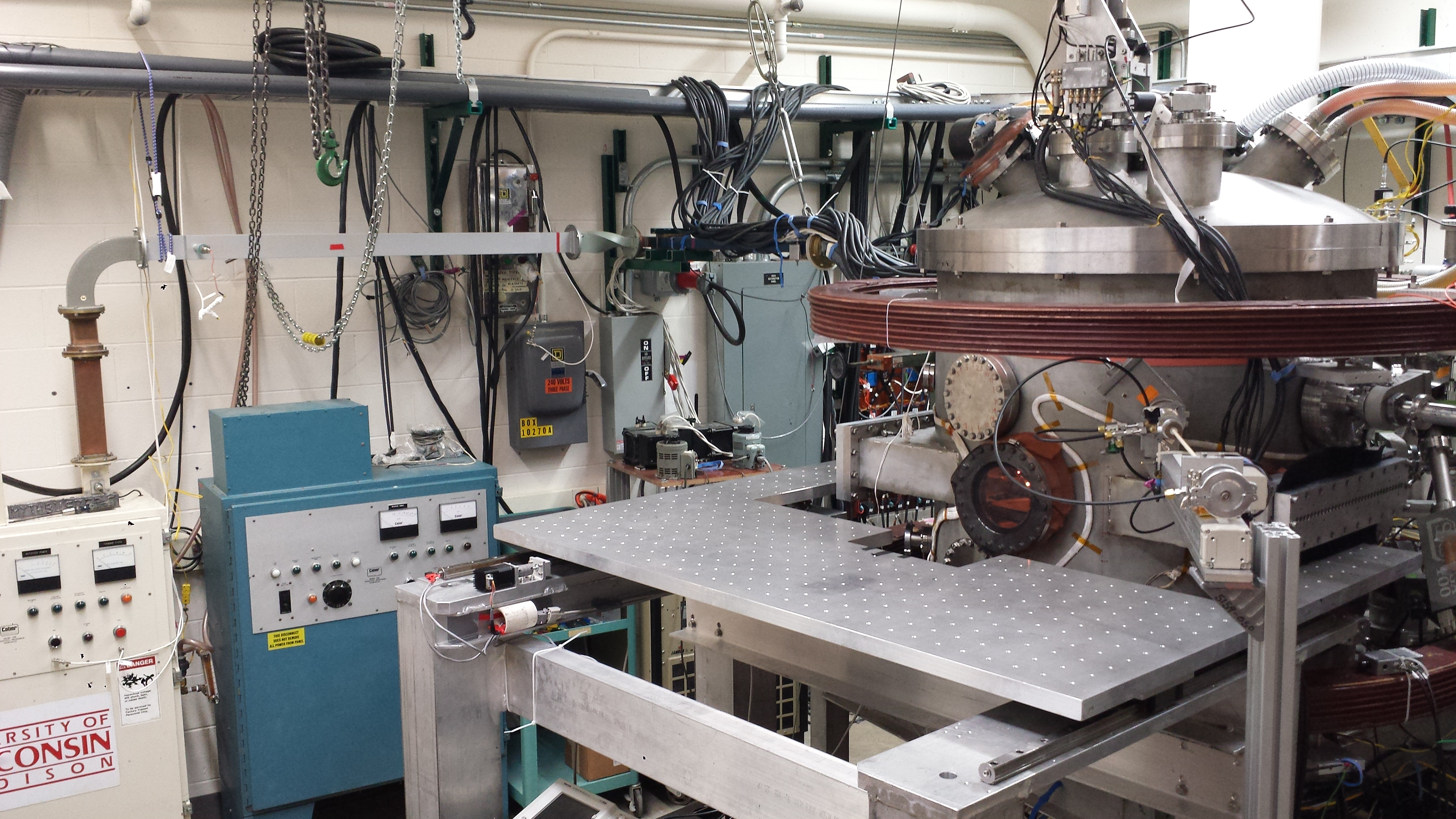

The Plasma Couette Experiment (PCX) is the device that I have done most of my graduate work on. The core of the experiment is a 1m tall by 1m diameter stainless steel vacuum vessel that can be pumped down to pressures less than 1 billionth of atmosphere. Inside the vessel is a set of rings of permanent magnets spaced roughly 1.5” apart that alternate in polarity. When a plasma is created inside of the magnet cage, the magnets act to confine it to the inner volume. The plasmas created in PCX serve as analogs to astrophysical plasmas, reaching temperatures of roughly 100,000 degrees celsius. This extreme heat is actually not too much of a problem because the plasmas are so much less dense than the air around us (about a 100 million times less).

When I first started working on PCX, the magnet cage system was built up of relatively low strength ceramic magnets (just like the ones on your fridge). The lower magnetic field strength meant that the experiment could not hold hotter and denser plasmas, which are a closer match to the astrophysical plasmas we want to study. On a small budget, I designed a whole new system to hold high strength samarium cobalt (SmCo) magnets and water cool them. The magnet upgrade would not only allow for hotter, denser plasmas, but it would also make the inner plasma volume of PCX larger by using more of the space inside the vacuum vessel. Also, SmCo magnets have a much higher Curie point than ceramic magnets, so the heat tolerance of the system would be much better (still needs water cooling though!).

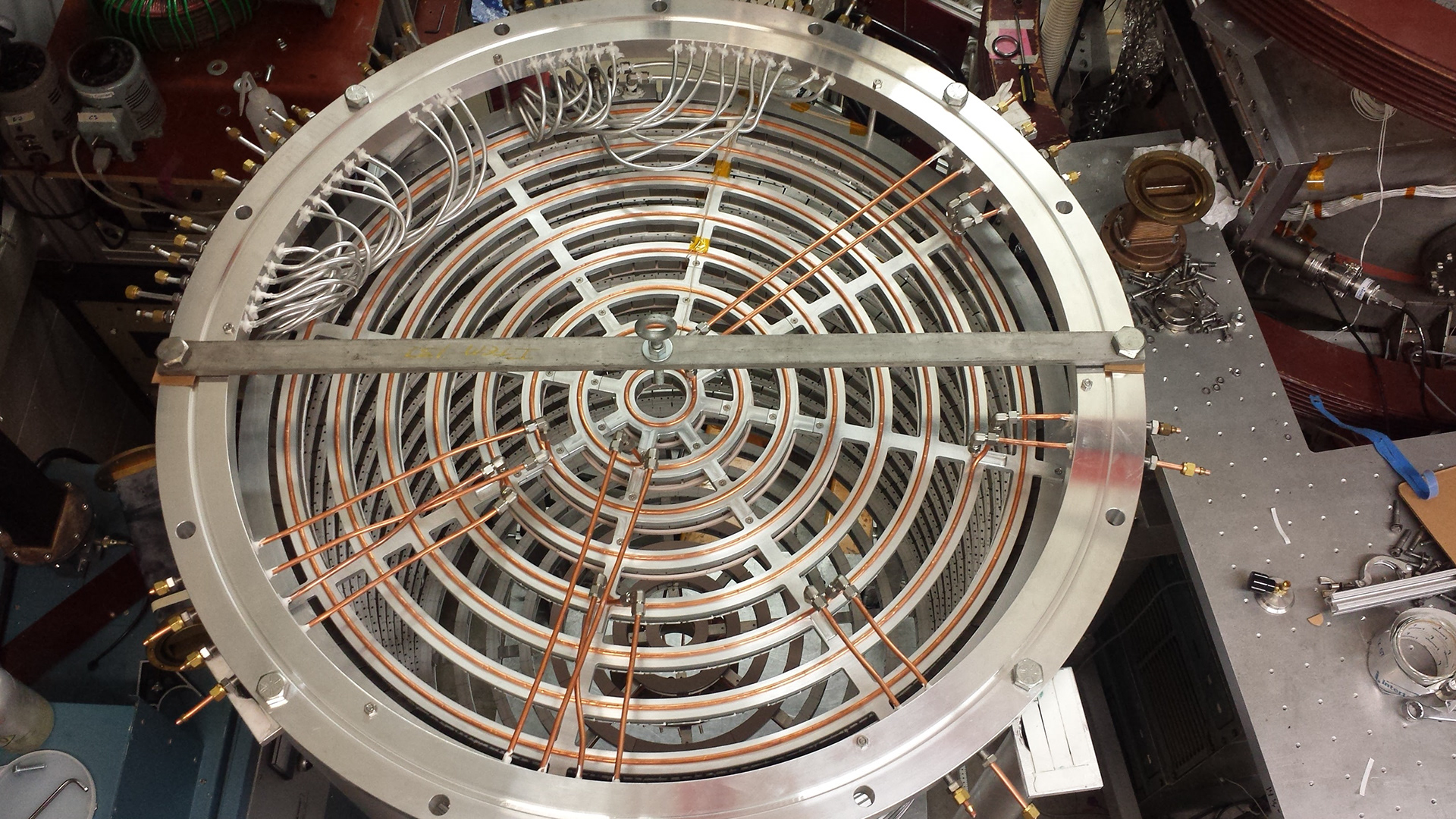

After a fair number of revisions, I settled on a final design for the upgrade. It consisted of nearly 2000 magnets spread around 32 individual rings. Each ring is water cooled in its own loop, so that meant that there needed to be 64 separate water cooling feed throughs into the vacuum vessel, which meant I had to design a custom manifold that housed the feed-throughs as well supported the entire ring structure. Finally, I designed 16 of the rings to be a custom aluminum extrusions with built in water cooling channels that would then be bent into the correct diameter to fit inside the vessel. Assembly was going to be a lot of work…

After a fair number of revisions, I settled on a final design for the upgrade. It consisted of nearly 2000 magnets spread around 32 individual rings. Each ring is water cooled in its own loop, so that meant that there needed to be 64 separate water cooling feed throughs into the vacuum vessel, which meant I had to design a custom manifold that housed the feed-throughs as well supported the entire ring structure. Finally, I designed 16 of the rings to be a custom aluminum extrusions with built in water cooling channels that would then be bent into the correct diameter to fit inside the vessel. Assembly was going to be a lot of work…

The custom extruded rings were ordered from a manufacturer I found on Alibaba in order to keep the cost low. The rings were well made and bent to within the requested specifications, however, they were twisted out-of-plane, which wasn’t going to work for the confinement system. As a result, I ended up heating them to roughly --- and then pressing them with nearly 2 tons of weight. This helped flatten them, but it took the temper out of the aluminum, which made machining more difficult. After the rings were machined with flats for the magnets and tapped holes for mounting them, assembly began. This involved carefully cleaning everything that was going to go in the vacuum, hand placing every magnet and installing all the water cooling lines.

The water cooling proved to be pretty difficult because I had created a very tight fit for many of the connections. In retrospect, I should have been a little kinder to myself, but it worked out in the end. All the water cooling connections were exhaustively tested by with a helium leak checking unit and were sealed with vacuum putty where needed. After installing the system and pumping down the vacuum vessel, some leaks became more apparent and a special sealant was used in the leaky water tubes. After a decent amount of work tracing these leaks down, the water cooling can operate at full pressure (~50 psi) under a complete vacuum in the vessel continuously with no leaks. The completed magnet upgrade has made a significant improvement to PCX plasma performance, improving the ionization fraction of argon plasmas from about 20-30 percent to 60+ percent.

Plasma Couette Experiment (PCX)

Fisheye view of the inside of the vacuum vessel after the upgrade.

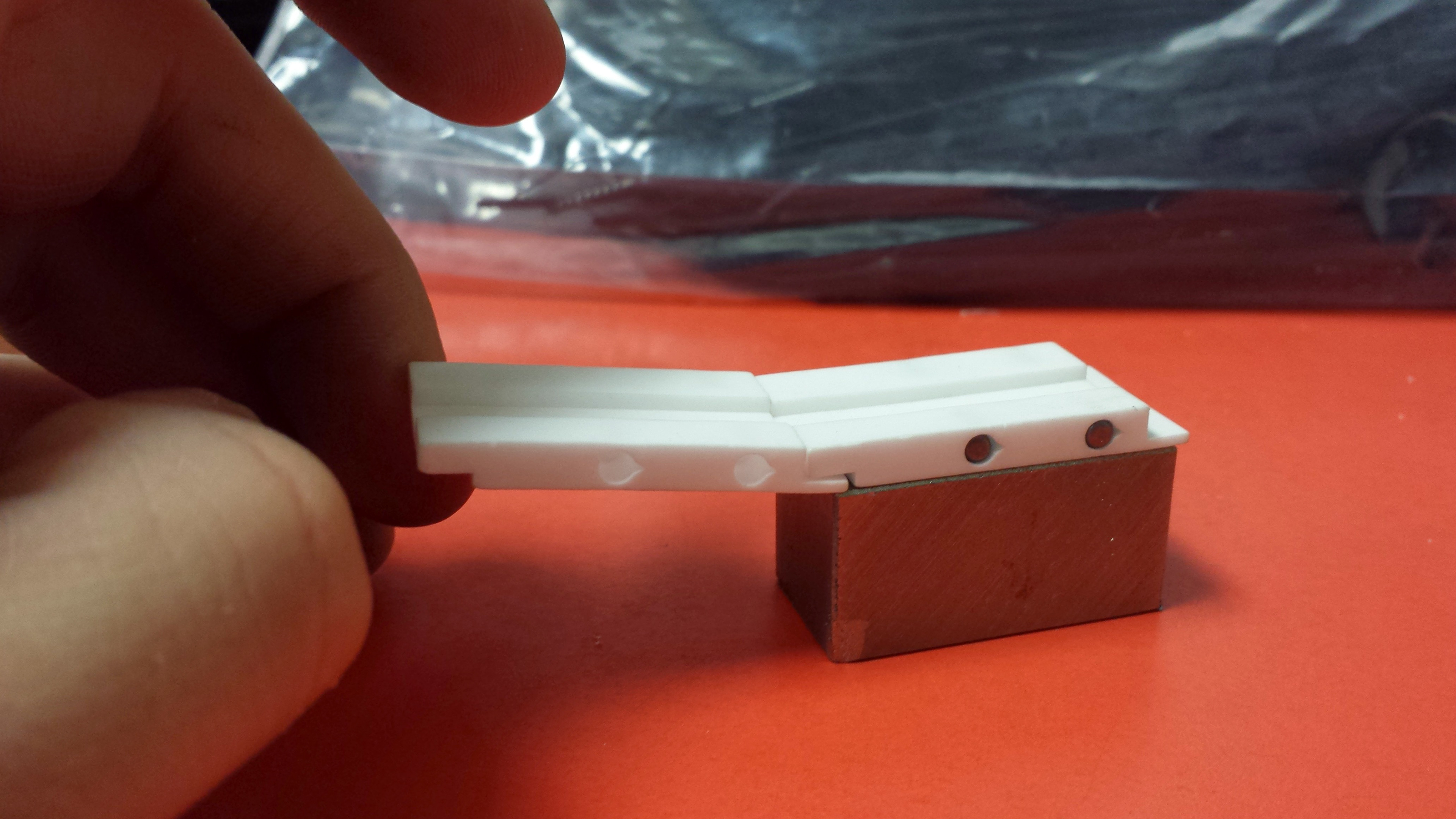

Magnet and ceramic tiles.

A warped ring wrapped with heat tape before being covered with 2 tons of weights

Drill press rig for drilling and taping the mounting holes for the magnets

All 2000 magnets were carefully placed by hand

The magnets are held to the rings with a countersunk screw

Water cooling lines that run to each extruded ring.

Top down view of the magnet cage before installation.

Mike Clark (group engineer) and I hoisting the new magnet cage over to the vessel